When conceptualizing a customized Android device, the 3 main areas to focus on are casing (mechanics), electronics, and firmware. Other aspects may include accessories and packaging (depending on business model), to name a few, but this article focuses specifically on the Android device itself. Key factors within each area affect the development cost and time and unit cost. Understanding what impact different factors have enables a more efficient and beautiful development process. Read on for a summary of key details that matter in custom Android development.

Casing

Casing is unique as it incorporates two different disciplines of design; external and internal design. Usually called Industrial Design and Mechanical Engineering, respectively. If good looking external design isn’t a key aspect for your custom Android hardware then using just a mechanical engineer for both should be fine. Many mechanical engineers mistake themselves for industrial designers anyway. Usually external design means less for products that users don’t see or are purely functional in nature. For the sake of this article we’ll look at the best way to approach a product where design matters.

External design, unlike all the other areas covered here, is exclusively based on perception and emotion. Intricate details affect branding, perception, and usability. Hatch highly encourages our customers to work directly with an industrial designer (rather than through Hatch or any other final product supplier) on the case’s external design for the highest quality results. Hatch will provide the dimensions and other relevant information to support the designer. To allow a smooth transition to the mechanical designer, the industrial designer should define gap tolerances between the parts of casing, exact colors, and materials. Usually industrial designers do a good job on the latter two, but making the case fit perfectly can take a lot of time. Having this requirement from the beginning gives a clear goal, allowing a supplier to test internally before sending to the client.

It’s best to use a mechanical engineer with product specific experience to create the mechanical design. That’s why Hatch takes control of mechanical design once external design is finished. Hatch’s mechanical designers have made and modified hundreds of Android devices like tablets, phones, and custom hardware. Without start to finish product specific experience even a very qualified mechanical engineer won’t foresee product specific design nuances. Those nuances are related to finished product quality and, through support of supply chain partners, component selection.

Only through seeing multiple products go from start to finish do hidden design optimizations become clear; this is the definition of experience. For example structures within the mechanical design to strengthen ports or block dust from entering the screen area. Sometimes ‘the perfect’ design requires an expensive or difficult to source component. That must be avoided (and there’s no such thing as perfect design). Collaboration between Hatch’s experienced engineering team and a client’s mechanical designer combines the best of both worlds. This has a higher cost for the client and maybe overkill, but certainly covers all bases.

Simple takeaways:

- Make sure your industrial designer specifies gap tolerances between parts of casing.

- Use a mechanical engineer with Android device experience for expertise with quality manufacturing details.

- Have the mechanical engineer work with a supply chain partner (like Hatch) to verify that the components suggested by the industrial designer are easy enough to obtain now and into the foreseeable future.

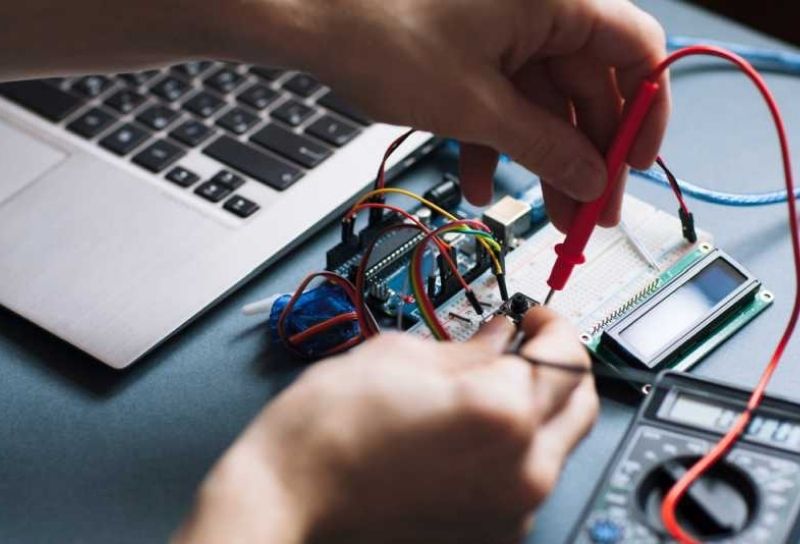

Electronics

All projects have specific performance requirements that call for different kinds of electronics. Potential for remorse comes when choosing commodity components like a screen or battery, designing around that, and then finding out that the screen isn’t crisp enough or the battery doesn’t last long enough. When customizing an Android device choose components individually, by testing them in other devices first. If there’s a screen you’re considering then get a sample of another device that uses the same screen to see if you like it. Once you decide on all the key components then make an initial prototype to check that they work well together.

As much as possible stay within the framework of the CPU manufacturer’s reference design. Clients have asked for a certain Bluetooth chip that’s not included in the reference design. A change like this requires changing the tried and true reference design. This change opens the door for new bugs. It also takes a lot of engineering to make this modification. Changing the reference design usually comes with a high development cost and higher mass production risk.

Simple takeaways:

- Sample key components individually in existing products before deciding on the final list.

- Test a prototype that integrates those chosen components before making mold.

- Stay within reference design; changing it opens the door to unpredictable problems.

Firmware

A combination of knowing the result you want from customized Android firmware and clarifying what customizations are possible at the onset of a project sets the stage for smooth development. The key here is to ask specific questions to the right people so you get reliable answers. Many Chinese suppliers hire inexperienced sales people based on their young age and English ability. Young means they’re cheaper and English means they can serve as a conduit of information to the customer. Oftentimes the answers these people give customers are incomplete or just wrong.

Hatch uses direct connections with IC companies and their licensed engineering companies to directly access management level engineers. While the engineers don’t usually speak English that’s not a problem and we’re usually able to get real answers about implementing complicated customizations. Like proper directions before a new journey, knowing whether the customizations you want are feasible avoids going in the wrong direction.

Simple takeaways:

- Clear definition of what’s needed before starting the project.

- Find the right person to confirm feasibility of customizations saves losing time going in the wrong direction.

Any project that tackles the unknown is prone to risk and surprise. Applying the takeaways, learned through first hand experience, listed above when approaching the project will maximize reliability while intelligently managing risk.