How to value custom Android hardware

I like having an expectation of price when buying something. You probably do, too. An expectation makes judging value easier. Human nature has something to do with this. It’s clear if some products are priced fairly or not. For example commodities like gasoline or bananas. Quality of common grades of gas or breeds of bananas don’t vary greatly between different sellers. Therefore pricing shouldn’t vary greatly either. Many products we routinely buy, whether for personal or business use, fall into this category for the most part.

The closer a product gets to the customer the more potential for adding value. This seems to apply universally, from custom Android projects to dinner. On one end of the food spectrum is something simple, cheap, and low quality, but edible, like instant noodles. On the other end is a culinary experience of globally sourced ingredients, prepared to the exact specification of a culinary artist, and served in a majestic environment. Both fight hunger, albeit are priced very differently.

What justifies the price difference beyond the cost of ingredients? In the example given above it’s the ambiance, presentation of the food, and taste. The value customers feel from a high end restaurant experience far exceeds the cost of the actual food. Buying products follows the same logic. A mass produced product that is similar to many other products has little added value. For example, a pair of generic headphones usually costs only slightly more than the seller paid for it themselves. Customers pay more for branded products, even those that are very similar to an unbranded product. The higher price comes from the reliability, quality, and sometimes prestige the brand represents.

Not all customers value things the same way. For some the brand matters, for others they just want the commodity. The value a custom product manufacturer brings differs from the value a commodity commodity device seller provides. The custom device manufacturer needs to spend more resources developing the custom device even though the volume is lower for a custom device than a mass market device. Custom Android device buyers often have niche use cases that deliver a higher value to the end user as well. More work goes into making a custom product. That means the product must deliver a higher value to the end user than a commodity product; the same way a dining experience delivers a higher value than instant noodles.

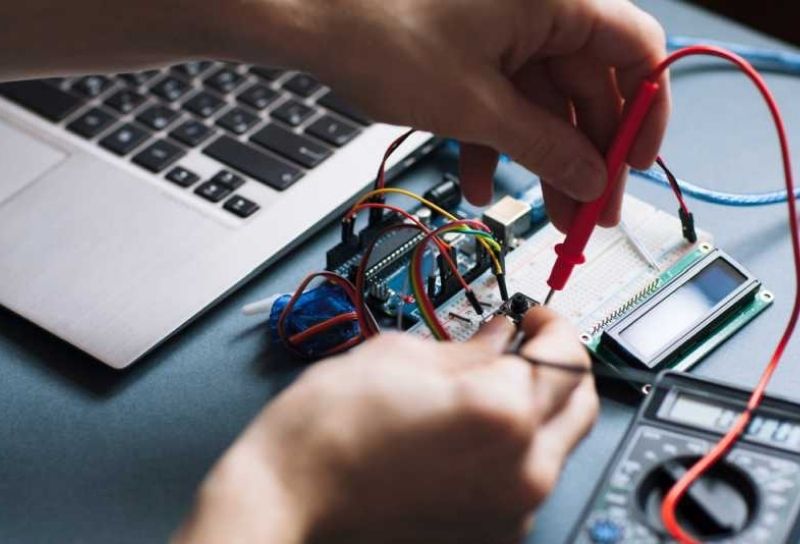

Most of Hatch’s customers use their custom Android products for business applications. Their products offer a high value to these businesses and require a manufacturing partner that offers an equally high level of service and knowledge. If a commodity product breaks the customer simply exchanges it at the retailer. If a business product breaks that means a company is losing money by not having it work. Also fixing the problem costs more than exchanging a product at a retailer. It usually requires a technician to deal with the problem. Business buyers should look at commodity costs as a clear point of reference. The art of determining a fair price for the added value comes from quantifying a supplier’s capabilities on one side; and the cost of something going wrong with the project on the other side.

“No one got fired for hiring IBM” is a saying which means that IBM has such a good reputation that an employee would never get fired for hiring them, even if a problem arises. Many highly skilled companies are small and don’t have the reputation of large competitors. When evaluating a partner for a custom project, it’s necessary to understand exactly what additional value the partner will bring. To do this, find out what kind of projects the partner has worked on before. Ask for referrals from past clients. Take into consideration how quickly and precisely the partner communicates. If they offer sensible and clear answers from the beginning that’s a good sign. If not then don’t expect them to start after paying the deposit.

Up front due diligence requires digging into the details of how businesses operate. Spending time to get comfortable with a potential partner increases the chances of success for your project.