Read about the lessons we’ve learned from doing custom device manufacturing and learn why prototyping is such an important stage in the development of your custom Android device.

Continue readingHow Is Android Revolutionizing Our World?

We take a look at the numerous uses of Android, and why more companies, including startups, turn to the free platform for their future projects.

Continue readingHardware Manufacturing: 3 Important Issues to Consider for Your Startup

Considering to get into hardware manufacturing? Here are 3 Important Points for Your Startup to Consider.

Continue readingHow to Manage Your RMA?

What’s an RMA? Discover how you can limit your financial loss from returned products through careful management of your RMA.

Continue readingChinese Sweat Shops Shifting Into High-Tech Manufacturing

While it’s true that Chinese sweatshops with 15-hour work shifts still exist, more and more factories are shifting to high-tech manufacturing and better salaries. Find out why.

Continue readingShould You Manufacture Your Smartphone In China?

This is an interesting subject to think about. Chinese goods are always looked upon with contempt.

They are cheap, unreliable and not meant for the American or European market. At least that’s the general opinion.

Obviously, Chinese smartphones just can’t compete with the greats like iPhone and even Samsung.

This is where you go wrong. Lately, there have been many Chinese smartphone manufacturers who have started competing head-on with big names.

Are Chinese Goods Made Of Poor Quality?

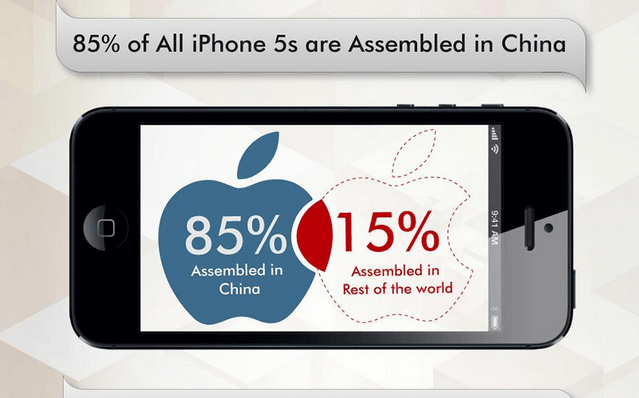

Did you know that 85% of iPhones are assembled in China?

If iPhones assembled in China can be of such high quality, there is no reason why other smartphone manufacturers cannot produce quality goods.

At the same time, it’s also true that most Chinese manufactured products are inferior. There are several reasons why there is such a variance in quality.

The foremost reason is quality control. Local Chinese manufacturers in their hurry to roll out their smartphones avoid or downright ignore quality control aspects.

This is a recipe for disaster. However, these enterprises justify their casual attitude claiming that the rock bottom cost of their devises compensates for the poor quality.

The consumer in China is also not bothered as long as the price is cheap. These manufacturers fail miserably when they try to sell in mature markets like US and Europe.

The quality of a product clearly depends on our attitude and emphasis. Choosing the right partner and manufacturer in China is critical to your success.

The second reason for churning out poor quality devices is the quality of components and raw material.

Sourcing the right components is an important factor in the overall quality of finished product. This aspect is tougher than it looks.

Discriminating between bad and good suppliers requires knowledge of the local market and environment.

There are many fly by wire operators who simply vanish after pocketing the advance. Chinese market is quite tricky and many US and European enterprises have burnt their hand here. You should therefore be extremely careful while choosing suppliers.

The third reason impacting quality is the actual manufacturing process. The factory facilities can make or break a product.

Seasoned outsourcing experts are aware of this fact and therefore choose manufacturing and assembly partners with extreme care.

Cost is sometimes a reason why some may turn to unknown Chinese manufacturers. This is not a good practice since culturally the locals are known to cut corners, eventually leading to sub-standard products.

The Culture Factor

More than anything else, you have to understand the culture and mindset of the local Chinese businessmen.

There is a tendency to make a killing from a single contract and there is a lack of long term commitment.

This psychological barrier has to be somehow breached if you want to produce quality products in China.

One way is to get US or European management to handle the manufacturing processes in China.

These professionals know the Chinese market well and can ensure that your product is manufactured using quality components and in a proper factory environment.

In the end, the cost incurred in engaging a professional unit can be easily justified and compensated by superior quality products.

This is an interesting subject to think about. Chinese goods are always looked upon with contempt.

They are cheap, unreliable and not meant for the American or European market. At least that’s the general opinion.

Obviously, Chinese smartphones just can’t compete with the greats like iPhone and even Samsung.

This is where you go wrong. Lately, there have been many Chinese smartphone manufacturers who have started competing head-on with big names.

Next-Gen Low Cost Android Tablet Chipsets

Allwinner vs. Rockchip

These new low-cost chipsets have allowed manufacturers to produce smartphones at record low prices and it has opened up a whole host of opportunities for other low-cost smart devices.

As component prices fall and technology improves, we are beginning to see more and smarter products at very affordable prices.

IC (integrated circuit) companies, OEM’s (original equipment manufacturers) and retailers alike are all pushing for higher performance in their low-end product lines, and this is being made possible because of the drop in component prices.

IC companies are beginning to make a real impact by releasing new SoC’s (System on a Chip) that are very powerful yet inexpensive and have lower power consumption.

These new low-cost chipsets have allowed manufacturers to produce smartphones at record low prices and it has opened up a whole host of opportunities for other low-cost smart devices.

Too many companies in the Android market the IC chipset or SoC is the linchpin within the supply chain. It is fundamentally the brain of any product.

Further, its performance and price dictate the type of smart device that can be created. As low cost /high-performance SoC’s are released we see a more significant shift in the market.

Manufacturers are for the first time being able to create much lower cost higher performance smart products.

Benchmark Testing

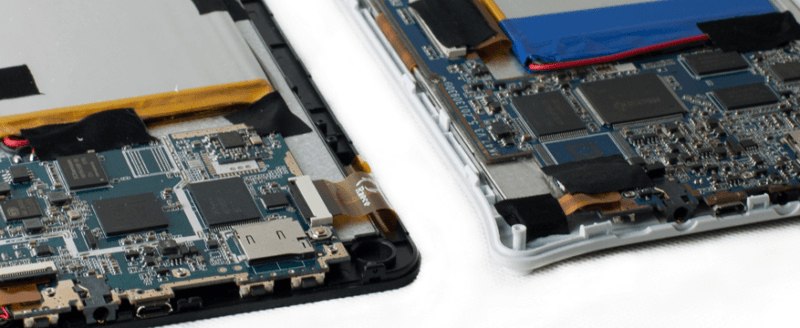

In September we saw the release of two comparable, low priced SoC’s from two of the top Chinese IC companies, Allwinner and Rockchip.

Only one month after their official release’s OEM’s launched tablet solutions powered by these chipsets.

Hatch performed key benchmark testing for samples of both chipsets, the A23 from Allwinner and RK3026 from Rockchip.

On paper the main difference when looking at a direct comparison is the CPU architecture:

- Rockchip is using the newer more powerful ARM® Cortex™-A9 architecture and is clocking a frequency of 1GHz, whereas

- Allwinner has the power efficient ARM® Cortex™-A7 clocking at 1.5GHz.

They have both chosen to use the same GPU, ARM Mali-400 MP2 Dual Core graphics engines, making a head-to-head performance test all the more interesting.

Allwinner has far higher on-chip integration because of MIPI DSI meaning there are more components on the SoC so developers can have fewer system components.

A higher on-chip integration allows for lower production costs and a more stable and efficient PCBA board. Rockchip, on the other hand, has potential cost-saving benefits with Pin to Pin compatible with the single core RK2926.

It means that manufacturers will not have to change the PCBA layout to accommodate the newer chipset.

It will be attractive for existing developers as upgrading from previous PCBA designs to the dual core will be less expensive and faster to market.

The results of the benchmarking made a clear distinction between the seemingly similar SoC’s.

Here’s what we found:

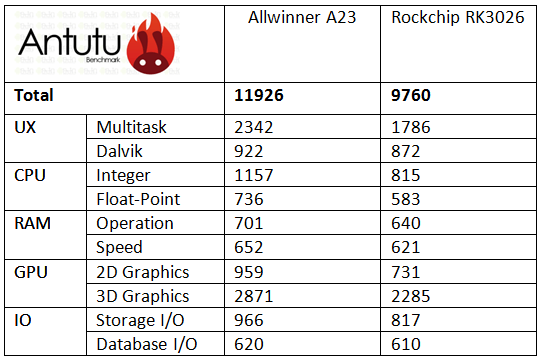

Antutu Benchmarks

Looking at the Antutu Benchmark scores, it is clear that the A23 has outperformed the RK3026.

This is due to a number of key differences in their design. First, the Allwinner clock speed has a 50% premium on the Rockchip which instantly makes a difference in performance.

You might say that as the Rockchip has used the more powerful ARM® Cortex™-A9 architecture this performance difference will balance out, but the CPU architecture isn’t the only factor at play when gauging performance.

Allwinner has invested in optimizing the A23 SoC’s system design allowing for better performance and more efficiency.

Also, DDR and GPU design enhancements have been made within the SOC that has positively affected the performance.

Further, the A23 utilizes a low power output specifically with audio and video playback at 50mA due to the use of the more efficient ARM ® Cortex™-A7 architecture. We think this will certainly be attractive for developers entering into the tablet space.

This being said what makes the RK3026 still stand out as a top SoC for developers is the 2G communication support allowing for cellular-wireless connectivity in next generation budget tablets and low-cost smartphones. But as of this month, Allwinner will release the A23 with 2.75G connectivity.

We will have to wait and see which solution comes out on top, but some industry experts believe the A23 has more specific peripheral communication interfaces.

This advantage in communication interfaces could gain A23 more industry support than the RK3026.

Looking at the unit price they are fairly comparable but the RK3026 PCBA cost has a slight advantage of being cheaper by 2-3%.

As this is marginal, we don’t think it will affect a developers decision, but it could make a difference.

After reviewing the two SoC’s it’s clear that we are seeing two great, aggressively priced consumer level platforms.

Choosing between the two really depends on your application. If you want a more powerful, more efficient SOC, go with the A23.

However, if you are looking for a smoother transition when upgrading from the single core RK2926, then the dual core RK3026 is the right SOC for you.