How to Connect with the “Laoban”

When doing business in a country like China you will undoubtedly face your fair share of problems. Putting China’s history, cultural differences, and government policies aside, you still have to contend with the language barrier. But the pros of high volume and low cost quality manufacturing are unlikely to scare any prospective company away. This is where focused relationship building comes into play. If you are doing business in China or want to do business in China you need to understand how the Chinese conduct themselves in business relationships.

Business relationships differ on many levels but the standard Western viewpoint is a win/win proposition where a contract between two parties is designed for their mutual benefit and eventual long-term growth and profitability. This approach may be ideal for the Western world, but when venturing into China, business relationships change and can become far more complex and personal.

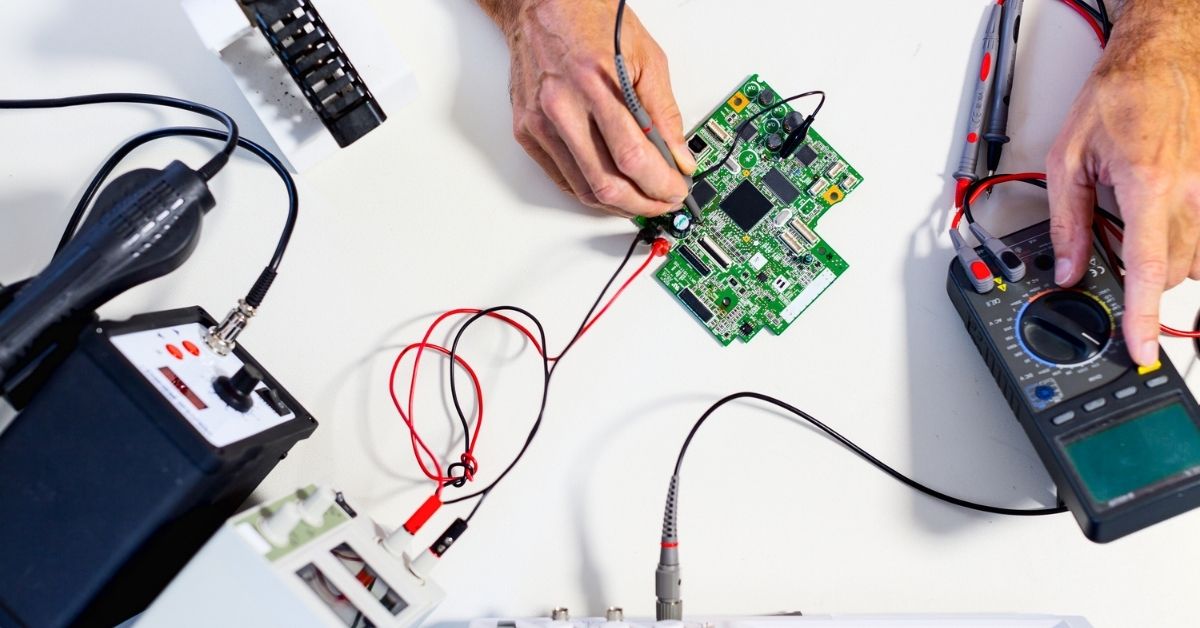

When you first establish a relationship within China it is important to come across with conviction. If you are sourcing a factory through Alibaba.com or another similar website you will likely be contacting a salesperson. He or she receives numerous emails from people with false claims with the intension of getting pricing quotes to leverage against existing factories or with other non-productive intensions. This means factories will likely dismiss non-genuine and also low-volume inquiries. The key is to come across with genuine interest. State what you want, state the quantity, and state your market. If possible, visit the factory at a trade fair or on its premises since meeting face-to-face will only help build rapport and prove your commitment.

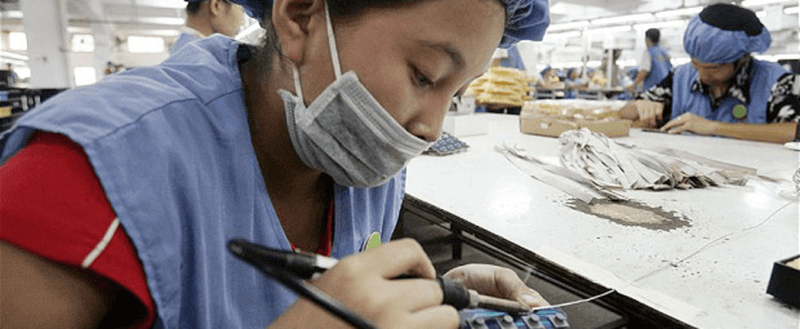

After establishing this initial relationship, it is important to avoid believing the standard Western stigma of China as a producer of “cheap crap” with low wages and horrible human rights conditions. Harboring this impression is only going to be detrimental to your relationships. Doing business in China is not a get in/get out sort of relationship. Chinese factory owners dislike this attitude. Even though they will likely accept your order, it will not build good rapport. These factories can be valuable long-term partners for your company and also for your own personal growth. It’s the relationship you build with the “Laoban” owner or manager that can be the most beneficial. The rigid hierarchy within Chinese companies can lead to important decisions being made by the owner, so it is important to have this close relationship. This is why building strong personal relationships with business partners in China can, in the long run, increase your profitability.

Why Guanxi and Keeping Face are Important

Relationships are important all over the world, but when doing business in China the relationship is paramount. “Guanxi,” described most basically as the personal connection between two people, is the foundation of all business deals within China. Building guanxi takes time. It has the premise that if you can build trust with someone, he or she will do business with you. Alongside building these new relationships you need to maintain the old ones. Similar to having a close friend, it is not uncommon to offer meaningful gifts to your business contact’s friends and family, go for dinners and attend social events, and also offer mentoring and advice when there is no money involved. These thoughtful gestures will strengthen the guangxi relationship you have and open doors that would otherwise be closed to you.

It is important within a business relationship to see it as a partnership and to see every party as equal. Being aggressive or appearing to be above someone is disrespectful. It has been known that coming on too strongly when things don’t go as planned can result in a “loss of face” for the Chinese factory and an end to the relationship. This will happen regardless of what or who caused the problem. “Face” is very important in Chinese culture. “Face,” equated to Western values, means reputation. If you imply that people have made a mistake by messing up an order or failing to act on something, they will “lose face” and their reputation will be tarnished. CEOs in China have committed suicide after losing face and shaming themselves after bad business deals. This is why working problems out as a partnership, whoever is to blame, is a way to maintain these relationships and build deeper guanxi.

Whoever is to blame when approaching problem issues with factories, it is paramount not to lose your temper. You should stay relaxed and keep blame to a minimum. The way to resolve issues like this is to forget who is liable and work out a solution. Use W. Edwards Deming’s rule, “Focus on the process, not on the people.” Chinese factories typically don’t accept returned goods and will help out only if you deal with the situation appropriately. Conversely it is important not to be perceived as a pushover. Respect your Chinese partners but also politely demand respect back.

Establishing and maintaining relationships in a foreign country can be challenging but can pay off by being respectful and patience. If you approach situations in China with the correct attitude you will “keep face”, build guanxi and then you can see profits in your business as it flourishes.