Different companies have different reasons for making a custom Android device. For some companies the case design isn’t one of those reasons. In this situation is there actually a reason to make a new case rather than using one that already exists?

A little background about using an existing case design. For the most part mass market Android devices are commodities, almost by definition. The technology, interface, and design of products with similar specs are fairly similar. It’s tough for white label brands to distinguish their products from other white label brands. With commodity products one company will supply a case, another company will supply the pcba, and other components, like screens, cameras, and batteries, come from their respective suppliers. The case, pcba, and other components end up in an assembly factory where they become a final product.

Companies that don’t need a custom case design have other reasons for making a custom Android product. Other reasons include having a more predictable and transparent supply chain or to make customizations to the firmware and/or electronics. When a custom case design isn’t needed, it’s possible to build the product using an existing, generic case from a mass market case supplier.

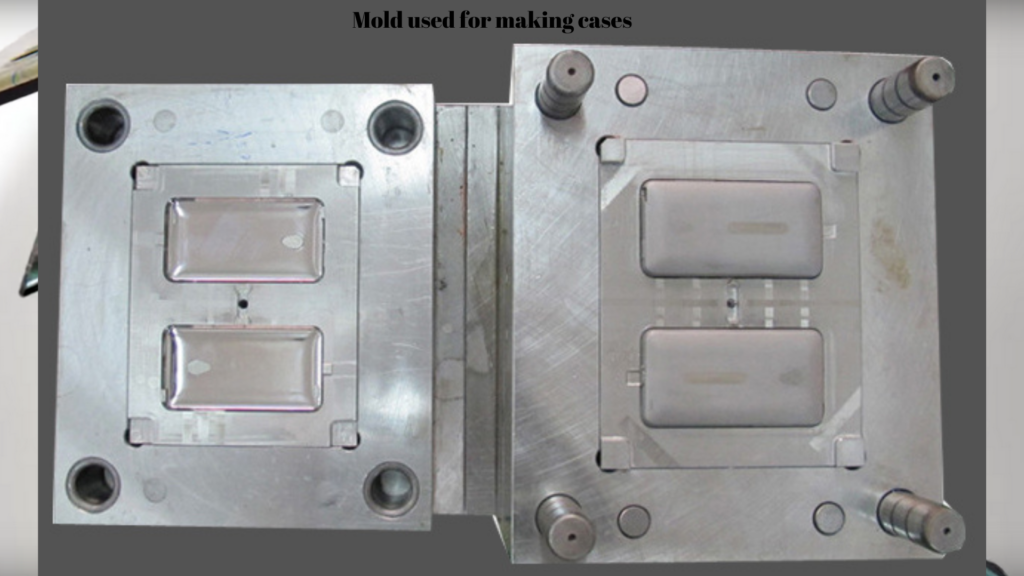

Benefits of Using an Existing Mold

The arguments for using an existing case are clear and valid. Using an existing case design saves the cost of making a new one. Using an existing case allows for faster development time since it’s not necessary to go through prototyping, manufacturing, testing, and modification processes. Product feedback from initial mass productions is also a good way to learn more about what customizations could be made to a caThe arguments for using an existing case are clear and valid. Using an existing case design saves the cost of making a new one. Using an existing case allows for faster development time since it’s not necessary to go through prototyping, manufacturing, testing, and modification processes. Product feedback from initial mass production(s) is also a good way to learn more about what customizations could be made to a case in the future. That way when the time comes, the investment of time and money in a custom case design has less risk. Faster development, lower cost, and education are strong arguments for using an existing case in the early stages of a new product.

Benefits of Making your own Mold

Once there’s stable demand for a new product, with regular orders coming in, it’s important to have an equally stable supply chain. This is where the value of having your own case becomes more evident. There are certain risks that come from sourcing a case from a third party supplier. Firstly if the company which makes the case goes out of business it will be difficult, if not impossible, to continue sourcing the same case. Knowledge of their closure may not be known until it’s time to make a new order, at which point it’ll become necessary to source a new case and most likely redo the electronics design.

Another risk is that, since other companies are buying the same case from the same supplier, the mold gets broken. This happens over time when molds are used often. Molds have different quality levels. Mass production molds usually have an expected production output of 100k – 500k, depending on the material used in the mold. If the case is popular and many customers are buying it the case supplier will usually fix the original mold or make a new one. If demand for that case has waned, the supplier may decide it’s not economically viable to continue producing that case. There’s also a small risk that a large client makes a deal with the supplier to give them exclusive rights to that case. In this case the supplier won’t be able to sell the case to other customers.

Summary

For faster, lower cost development, using an existing case, assuming that’s an option, has clear upsides. As order volume increases a company should look into making their own case to improve supply chain reliability. With higher volume orders, the cost of making a custom case becomes less of a risk as it reliably gets amortized into more units.