The foundation of all custom Android devices, as true with digital devices in general, is the CPU. Since all of an Android device’s core functionality flows through the CPU, its performance limits define the device’s features. When Hatch architects a new custom Android tablet the first step is defining the customer’s spec requirement and identifying which CPU delivers enough performance to match the requirements.

Choosing the right CPU is the first element of the development process because it’s the most critical. The right decision sets the path for a smooth development. The wrong decision leads to severe financial pain and lost time. Using a CPU that fails to deliver on the requirements renders the device useless, while choosing a CPU that delivers too much performance unnecessarily increases cost. The risk doesn’t stop there. There are many considerations to take into account. Here’s an example. Different CPUs support different sets of screen connector interfaces. Screen connector interfaces, like EDP and MIPI, vary based on the size of the screen and release date. Like all technology products, specs change with time. If the chosen CPU only supports MIPI, but the vast majority of screens that meet the customer’s requirements are EDP, the options of screens becomes limited, sometimes resulting in unstable pricing or availability.

CPU manufacturers come out with new chips every few years. Some become popular and stay in production for 7-8 years, while others fizzle out more quickly. Android CPUs are broken into 3 categories:

- Wi-Fi only. (Non-Telecom)

- Mobile data enabled for tablet size screens. (Telecom enabled)

- Mobile data enabled for mobile phone size screens.

Since the sub-7” mass market for Wi-Fi only Android devices is fairly limited, the CPU manufacturers don’t separate those CPUs by screen size. The Wi-Fi only CPUs are the only option for both large and small screen sizes. Even Apple barely pushes the iPod Touch, their small screen Wi-Fi only device, anymore, instead focusing on the iPad which has a larger screen. That being said, the lines get blurred sometimes. A lot of times companies will use a CPU that supports mobile data in a Wi-Fi only device for other features that it offers. Also, sometimes companies use CPUs that are intended for mobile phone screen size devices in larger screen tablets due to cost benefits, although there’s a limit to this because the mobile device CPUs rarely support anything greater than 8” screens by design.

Let’s take a look at the CPUs that Hatch has identified as today’s most popular Wi-Fi only chipsets.

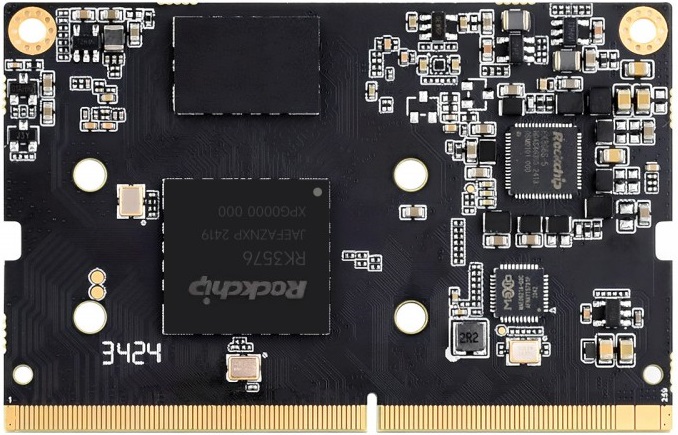

1. RK3576

The RK3576 is a powerhouse designed for premium devices, unveiled around 2022 by Rockchip. It combines Cortex‑A72 and Cortex‑A53 cores at speeds up to 2.2 GHz with the robust Mali‑G52 MC3 GPU, built on an advanced 8nm process. This manufacturing node not only improves performance but also significantly reduces power consumption, ensuring that the chip remains cool even during prolonged heavy use. In gaming tablets, the RK3576 excels with high‑frame-rate gaming and efficient thermal regulation that conserves battery life; in educational and creative devices, its efficient power draw allows for long sessions of interactive learning and multimedia editing. Brands like Chuwi and Teclast have embraced this chip, often in high‑end tablets, where stable energy usage under load is critical. Industrial applications also benefit from its balanced power consumption, combining high performance with minimized heat generation and energy wastage in environments with continuous operation.

2. MT8183

The MT8183, released around 2019–2020 by MediaTek, strikes an excellent balance between performance and efficiency with a blend of Cortex‑A73 and Cortex‑A53 cores and the Mali‑G72 MP3 GPU. Operating on a 12nm process, it is engineered to deliver robust multimedia and light gaming performance while maintaining relatively low power consumption. This efficiency is crucial for mid‑range tablets used in educational settings, where long battery life during remote learning sessions is essential. In gaming tablets, while it may not compete with premium chipsets in raw performance, its energy efficiency allows devices to run cooler and longer. Teclast, Fusion5, and similar brands have incorporated the MT8183 into products that emphasize balanced performance for streaming, multitasking, and interactive applications. The chip’s design also ensures a controlled power draw, making it a dependable choice in settings where consistent energy usage is as important as performance.

3. A523

The A523 from Allwinner, introduced around 2020–2021, is a modern, efficient processor built with Cortex‑A55 cores and a Mali‑G57 GPU that excels at 4K video decoding. Running at 1.8 GHz, its architecture prioritizes per‑core efficiency, and its design on a 22nm process ensures that the chip maintains a moderate power envelope. This efficiency is particularly beneficial in mid‑range tablets used for streaming high‑resolution media, e‑learning platforms, and moderate gaming applications. Brands like Alldocube and Chuwi have found the A523 to be a compelling option for devices prioritizing battery life and effortless performance in everyday multimedia tasks. In educational devices, longer battery endurance means continuous video lectures and interactive educational apps without frequent recharging. Moreover, while its clock speed is modest, the A523’s optimized power consumption ensures that devices can operate reliably under varied workloads without significant thermal throttling, making it a balanced solution for both entertainment and functional productivity.

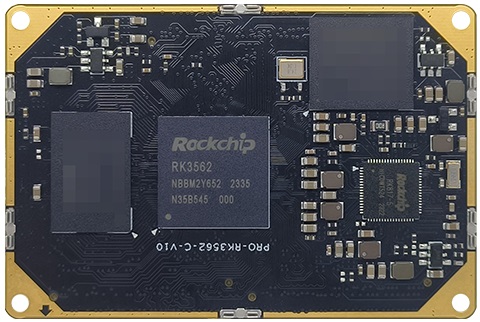

4. RK3562

The RK3562, launched around 2020 by Rockchip, is a budget-friendly SoC built on Cortex‑A53 cores running at 2.0 GHz and paired with a Mali‑G52 2EE MC2 GPU on a 22nm process. Although its process technology is not as advanced as newer nodes, it’s calibrated to deliver adequate performance while keeping power consumption in check for low-cost devices. This balance makes it an attractive option for affordable educational tablets that run interactive apps and basic multimedia, as well as for devices in industrial applications where energy efficiency is critical despite modest computing needs. Brands such as Cube and Alldocube deploy the RK3562 in markets where price sensitivity is paramount. Its controlled power draw ensures that basic tasks like web browsing, video streaming, and light gaming do not excessively drain the battery, making it a reliable and economical choice for entry-level computing while ensuring that operational costs remain low in energy-constrained environments.

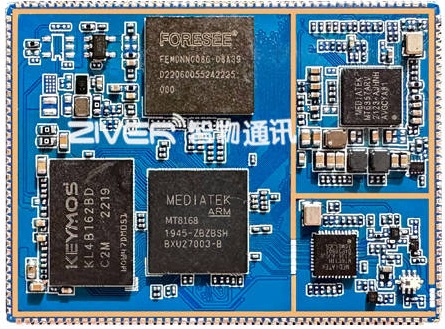

5. MT8168

The MT8168, introduced around 2018 by MediaTek, is tailored for entry-level tablets that demand basic functionality with efficient power usage. Engineered around the Cortex‑A53 architecture and paired with the Mali‑G52 MP1 GPU on a 12nm process, it offers reliable performance for everyday tasks such as web browsing, video playback, and e‑reading while maintaining low power consumption. This is especially important in educational devices that need to last through long school days or remote learning sessions without frequent recharging. Although it struggles with resource-intensive applications and high‑end gaming, its low energy footprint ensures that battery life is maximized—making it ideal for budget devices. The MT8168’s emphasis on efficiency appeals to emerging market brands focused on cost-effectiveness, ensuring that even devices built with limited hardware resources provide steady performance and reliable energy management for consistent everyday use.

6. A133

The A133 is an older entry-level processor from Allwinner, introduced around 2016–2017, that features Cortex‑A53 cores paired with the PowerVR GE8300 GPU, fabricated on a 28nm process. Its design targets lightweight applications in basic tablets and mobile devices, where power consumption is minimal yet sufficient for tasks like email, web browsing, and standard video playback. Though its higher process node means less energy efficiency compared to modern chips, it remains practical for devices geared toward low-cost and energy-sensitive markets. In educational environments, the A133 powers affordable tablets and e‑learning kits where simplicity and prolonged battery life meet basic computing needs, even if not suited for gaming-intensive tasks. Regional and budget brands have historically adopted the A133 for entry-level devices. Its straightforward architecture ensures a predictable power draw, which, while not optimized for modern intensive applications, reliably meets the minimum energy demands necessary for everyday, light‑duty use.