With the second half of the post I used GIFs and pictures taken live to give you an organized and insightful view of a Shenzhen prototyping factory. It is just like being there yourself. Don’t mind the partial nudity…

The first part of this article has been written to give you a better understanding of the topic but you can jump to the second half of this page to directly visualize the 10 steps of the CNC Rapid prototyping process.

Your prototype is an early sample of the hardware product you are looking to manufacture on a large scale and for this reason, it’s one of the most crucial steps during the hardware production process.

I. About CNC Machinery

In brief:

- CNC Prototyping is one of the many ways to do Rapid Prototyping

- CNC stands for Computer Numerical Control, in other words the computer commands the machine

- A 3D file of your product is needed on the computer to control the machine that is going to produce the parts (use a CAD software)

- CNC machinery works for plastic (like ABS or PMMA) but also for metal (like steel, aluminum, brass and so on)

- It is often used to make one single prototype but works fine to make up to a few hundreds parts

- CNC prototyping is fast and precise

- CNC results in a high quality prototype that’s very close to mass production quality,

- The cost is much higher than a mass production case (likely 50-200+ times more expensive)

- With CNC machinery, the high prototype cost remains reasonable compared to time and money investment in opening a mass production tool

If you want to go deeper into this topic you should check this excellent article written by Mike Lynch. It is an article from 1997 but still relevant today.

For a brief history of CNC Machinery you can also check out this 4 minute video.

II. Why does Hatch Recommend Paying for a High Quality Prototype?

A good prototype can be rapidly improved on and reliable (to look like mass production quality), especially when the time comes to validate its final version.

- Significance of ‘improved on’: understand that your first prototype will most likely be reworked since, with the (almost) real thing in your hands, you can discover technical weaknesses of your product and also, more importantly, how the user experience can be improved.

- Significance of ‘reliable’: you need a prototype providing a result extremely close to the reality of what it will be when produced on a larger scale. You need to end up with a prototype that reflects as close as possible what the customer will receive in the box.

So the purpose of a good prototype is not limited to verifying if everything will work sufficiently during mass production. It goes beyond that: it is more about testing your innovative idea and learning from its materialization.

For these reasons, the CNC prototyping is great. You can reach a level closer to perfection by quickly building a working prototype of high quality with a great look and feel rather than wasting time building an approximation of what your product will be which could trick you to make misjudgments about your product.

III. Case Design And PCBA Layout: Constraint And Perfect Match

For hardware prototyping, whatever your custom device may be (a smartphone, a tablet, a medical device, etc.), besides designing and prototyping the PCBA of your product you have to simultaneously consider the case design.

Indeed, because design matters so much, it will often constrain and drive the PCBA layout. A perfect match between both is required to ensure a custom device that works well and looks great. For this reason the precision of the CNC machine is crucial.

IV. Do You Really Need a Prototype of Your Custom Device Case Design?

The simple answer is YES! Would you ever build a house without a blueprint? Unless your product is so simple that a prototype isn’t necessary, which we’ve never encountered (no matter how ‘simple’ the product is), a prototype is a essential part in the development process.

Now that things are more clear, check below for an insider view of a prototyping factory in Shenzhen.

Enjoy!

V. Visual Insight of a CNC Prototyping Process in Shenzhen

1. Getting Your Product 3D File Ready

The process starts with the engineer programming the 3D file of the product with a Computer-Aided Design Software (CAD).

2. Choosing The Most Suitable Material For Your Prototype.

To build the prototype, two types of materials are used:

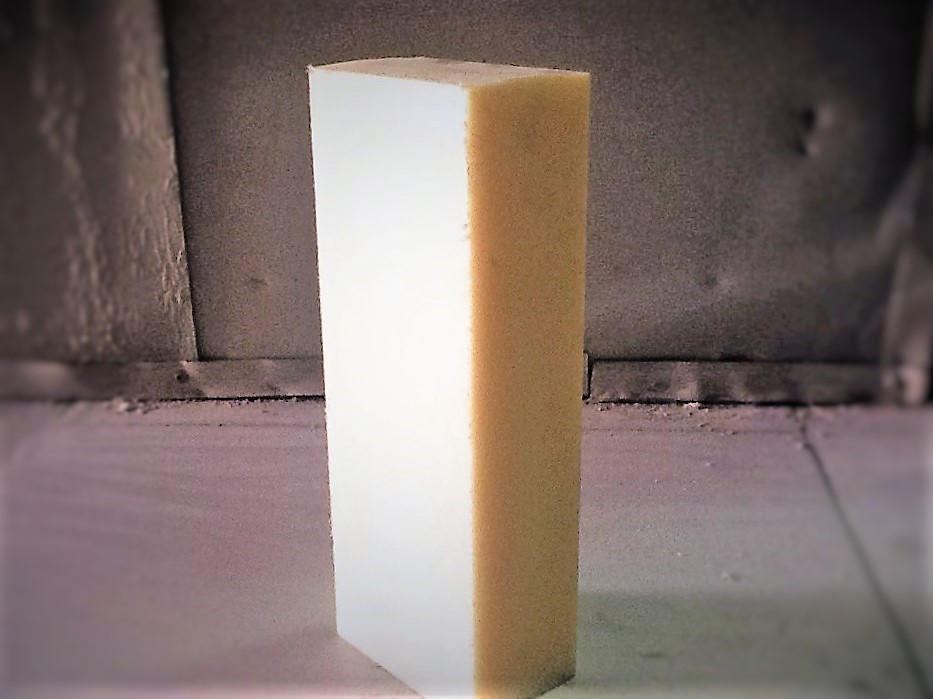

2.1. About blocks made of PMMA:

For prototyping PMMA is often used for transparent parts. Its chemical name is Polymethyl Methacrylate. It is originated from Organic Glass.

Besides transparency, PMMA is easy to stain, possesses chemical durability, is weather resistant, and is easy to machine with a good results.

2.2. About blocks made of ABS:

ABS is stronger than pure polystyrene. The styrene in it gives the plastic a shiny and impervious surface.

ABS can be used between −20 and 80 °C (−4 and 176 °F).

Its advantages are its resistance toughness and heat resistance.

3. Case Design Shaping

When the 3D file is ready, a CNC machine is used to shape the block.

3.1. 3D file data upload

The program data is uploaded into the CNC machine.

3.2. Shaping

The CNC high speed machine starts to shape the plain raw material according to the programmed file.

3.4. Monitoring

The CNC machines monitor demonstrates the work data.

3.5. Case Design Parts Removal

After the shaping is over, parts of the prototype are removed from the machine.

4. Preparatory Painting

Each part is painted and dried before being polished for the first time.

4.1. Painting

The color choosed doesn’t really matter here. Usually black is used since the purpose of the color is to see more clearly where the part has not been polished during the step that follows (see Section 5.).

4.2. Drying

The painted part is usually dried in a hoven. But sometime to accelerate this step lengh a simple hair dryer can be used too.

5. First polishing

The purpose of the painting is to ensure that all the surface of each parts are polished.

6. Trial Assembling

6.1. First Inspection

At this stage the parts are inspected before going further in the process.

6.2. Restoration of Imperfection And Defects

The smallest processed parts sometimes need to be hand repaired.

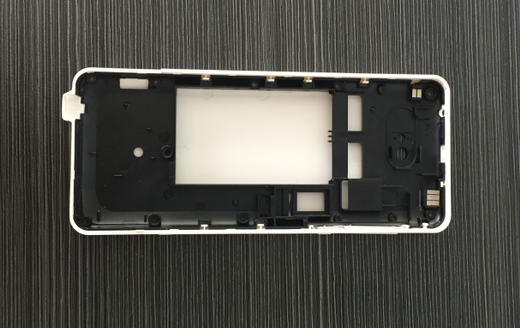

6.3. Regroupement of case design parts

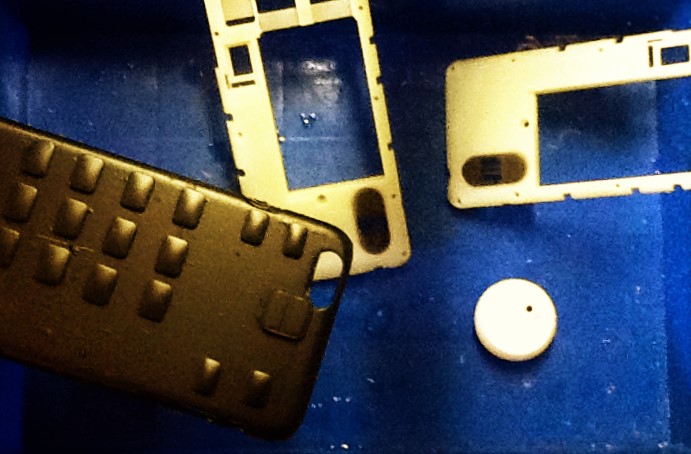

The finished parts are put together.

6.3. Trial Assembling

After all the processed parts are polished, a trial assembling is made by hand before each parts are painted separately with the required color.

7. Final Preparation of The Parts

7.1. Painting And Drying

Following the painting with the exact colors required by the client, parts are placed in a drying oven.

7.2. Second Polishing

The second polishing aims to leave a perfect finish.

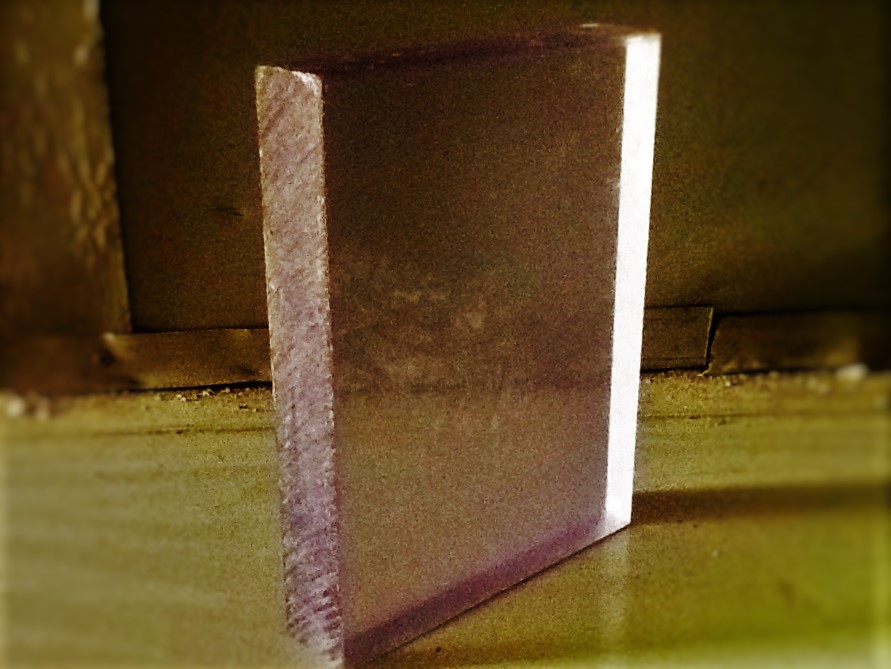

You can see the difference below between parts after first polishing (on the right) and after the second one with the exact color required for the prototype (on the left).

7.3. Final Inspection of The Custom Case Parts

Finished, painted and polished parts are inspected one more time before being assembled.

8. Final Steps

8.1. Assembling

Parts of the custom case are assembled with the custom PCBA.

8.2. Prototype Inspection

The prototype is ready for the final quality inspection that occurs just before being delivered to the client.

From there, the rest of the production process will follow and the end user ends up with a perfect product in hand

Disclosure:

The half naked worker and old furniture you can see on the pictures are not very sexy.

In their defense I should say that the Shenzhen factory culture is more about substance than style and the way they dress (or undress) in China doesn’t reflect at all the quality you can obtain for your prototype.

The topless worker reflects that Shenzhen is super hot in the summer. Regardless of these details, what matters above all are the kind of people who make it happen. You should always make sure that they have:

- the ability to respect and rigorously follow the prototyping process

- a great level of experience and precision with each tasks they are executing

- a healthy working environment where they are treated well and respected

China is inexpensive compared to western countries. For this reason, high quality can only be reached with:

- factories that don’t follow local ‘industry standards’ and have experience working with demanding clients, and

- has good management so its workers are long term

As long as the quality is controlled at several points in time by yourself or a third party company who can assist you with quality control and factory management, Shenzhen is definitely the right place to go for hardware development and manufacturing.

Some questions? Interesting experiences or articles to share about prototyping? The comment section below is all yours!

Lionel Beilin