Most companies buying custom Android hardware or mass market (retail) Android products rely on their manufacturing partner for hardware knowledge or, at least, after sales hardware or components. The industry standard duration of manufacturer warranties is 12 months from shipping or date of arrival (be sure to clarify this with your supplier!). It’s common for brands to provide warranties that eclipse the time frame provided by their manufacturers. When their supplier’s one year warranty ends, how do these companies deal with servicing hardware problems? Even during the warranty period the question of dealing with defects is complicated.

In the case of a custom Android product used for business or commercial applications the brand is responsible for maintaining hardware in perpetuity. Hatch’s clients typically make money from a revenue generating service delivered by Android hardware rather than selling hardware for a profit. The brand needs to maintain the product for longer than that. With retail Android brands, end customers usually get a 12 month warranty from the date of purchase. There could easily be 5-6 months between shipping from China and when a customer buys the product.

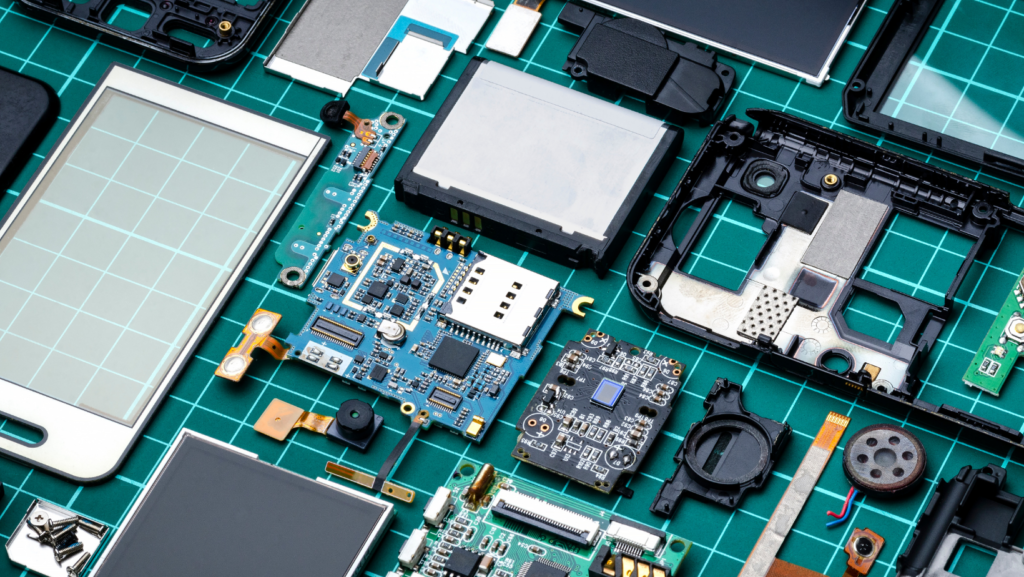

Get spare units to cover expected defects with each order. 1-3% is typical. Send out new units to clients to replace the defects. Get back old ones from the clients, then swap parts as more come in (hopefully it’s not always the same part that breaks). Alternatively get spare unassembled components from the supplier, if that’s a better option. Usually it isn’t though. Keep a record of the key components from each production that can vary by production run like screen, touch panel, and camera. Sometimes suppliers use components from different manufacturers. Label products by production run so it’s clear which production the defects came from. When components change the drivers, and thus firmware, will be different. Sometimes components change to save money, other times it’s because the originals aren’t available anymore. If it’s impossible to determine which part to use when fixing, usually firmware can support multiple drivers. Supplier support is necessary to get that done. Then update the firmware to use the one with all the drivers.

When vetting suppliers look for those with a long term vision and integrity. This has massive value in that the products are usually better quality and the supplier has more to lose if they’re not better quality. Try to judge these intangible traits during initial communication and during the sampling process. Choosing a supplier isn’t only about cost as the commercial relationship has many angles. Cleaning up the mess of the wrong supplier will cost much more in ongoing fees than the lower upfront hardware cost saves. If the supplier stands behind their word, they’ll honor their responsibility or look for middle ground solutions with the client.

Dealing with product repair in-house increases turnaround speed and usually lowers cost compared with sending the product back to China for repair even if labor cost is high. Without getting into too much detail it’s usually difficult to import defective products to China. This is as much a country issue as a supplier issue. China makes it much easier to export than import products. Defects usually are blocked at customs or charged a very high tax. Combining the cost of not having the product, tax, and shipping usually makes shipping products back to China economically disadvantageous.

The keys to handling after sales service are finding the right supplier (not easy, usually takes costly trial and error), learning how to fix products locally, having the parts available to fix the products, and knowing which parts to use in each product.