What supply chain means

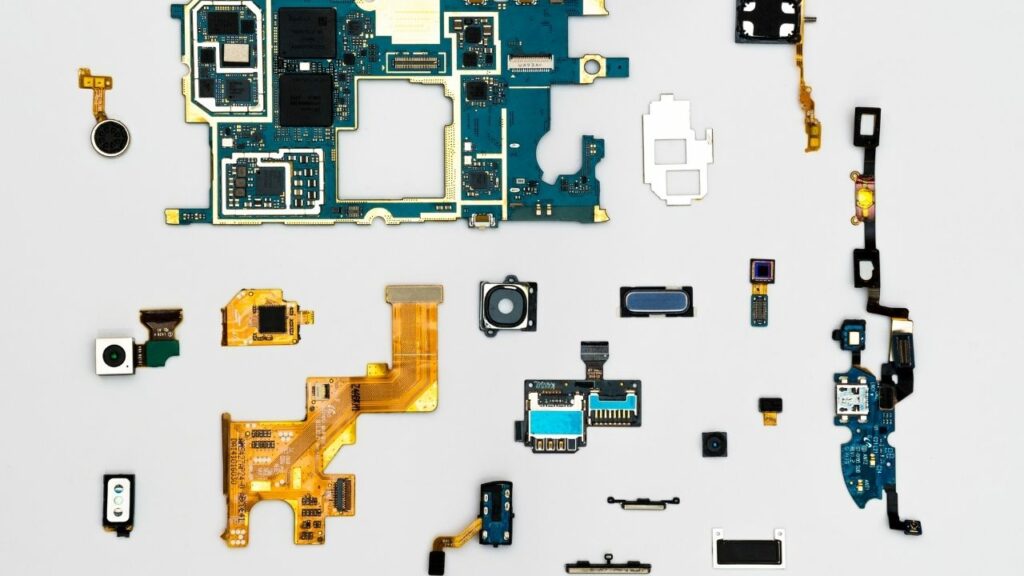

In this article ‘supply chain’ refers to all the contributors of components or services that go into manufacturing a finished product. More specifically, in the case of custom Android manufacturing, that means suppliers of hardware such as screens, PCBA, cameras, cases, etc. Also different specialized service providers such as electronics, mechanics, software, and assembly engineers. General services, such as logistics, which aren’t specific to Android hardware are not covered in this article.

What’s a mature supply chain?

Supply chains become mature when multiple suppliers gain expertise and compete on individual pieces of the supply chain. A supply chain consists of many different elements so when there are many companies competing in one niche of the supply chain, over time that creates optimal service and price (theoretically). For example there are hundreds of companies that design and produce plastic cases for electronics around Shenzhen. Several of them are particularly focused on designing cases specifically for Android tablets or smartphones. There are so many case suppliers and so much demand for Android device cases, some case suppliers carve a niche by specializing in tablet or smartphone cases.

This creates teams of engineers with specific retained knowledge that apply directly to making Android devices. Each case company has engineers with experience designing cases for optimal performance and manufacturing efficiency. For example an experienced mechanical engineer designs the camera slot in a way to ensure the camera easily snaps into place, blocks light from the flash, and doesn’t overheat. They know what works, and have seen many things which don’t, creating a reliable and efficient supply chain. More experienced component manufacturers working in a supply chain makes that supply chain more mature.

What’s an immature supply chain?

Supply chains are immature when there are limited suppliers with deep (or any) expertise in bringing a finished product to life. For example when developing a new product, especially taking that product from prototype to mass production, countless surprises and mistakes happen due to inexperience. It could be that the product was designed by non-Chinese engineers who choose components that are difficult to get in China, necessitating a design modification. Even for products fully designed in China, components don’t always work well together. Some materials don’t mix well together for chemical or electrical reasons. Some components come with different calibrations that require tweaking for consistency during mass production. Immature supply chains result in surprises that take time to resolve.

Production line staff at factories don’t usually understand the point of the custom modifications as it pertains to the product’s use case. Because of this sometimes small variations in workmanship have a bigger impact on product performance than the staff realize. Over time mistakes become lessons, but until that happens the supply chain is immature.

How does a supply chain become mature?

Immature supply chains become mature over time as orders of the finished product increase. For example when Android tablets first started shipping from local Shenzhen supply chains around the end of 2010 the product quality was low and unit cost was high. As demand exploded new suppliers entered the supply chain. Even with these new entrants it took a while to meet demand and have prices start to come down. Over time the profit margins decreased and maturity of the supply chain evolved. Once supply caught up with demand they needed to improve product quality and price in order to compete. Sales volume and, in turn, competition are the key forces that drive a supply chain to maturity.

The more orders suppliers produce the more opportunity they have to learn from mistakes. This drives improvement of their components and, ultimately, the finished Android tablet. As volumes of Android tablets and smartphones exploded a massive supply ecosystem came into existence. The same events take place in the creation of supply chains for lower volume products, albeit with relatively fewer participants, as demand is lower. A large company producing high volumes of a unique product will also create a mature supply chain. This happens somewhat through brute force rather than purely organic capitalism. In this case entering the supply chain is more restrictive than with a product anyone can buy since there’s only one customer who chooses the individual suppliers.

How to work with an immature supply chain

It’s necessary to work with an immature supply chain whenever creating a new product or modifying an existing one. Getting from idea to mass production means going through a learning curve. Over time production runs become more efficient by identifying and fixing problems. That’s why initial production runs should start with smaller quantities. Problems are easier and less costly to fix with lower volume.

In addition to extensive testing with low volumes, having multiple suppliers for high risk parts is also useful to hedge risk. High risk parts refers to parts that have a higher tendency to go out of production or become difficult to source. Often a component’s future availability is tough to predict. From experience, cameras and screens seem to have the highest risk in custom Android devices.

Supplier value in a mature supply chain

Once a supply chain becomes mature so do the buyers. Experienced retail buyers know what’s important to look for in a supplier. The supplier traits which matter most in a mature supply chain are quality, speed, price, and reliability. Because finished products coming from a mature supply chain are so similar to each other there’s rarely room for significant product differentiation. Strides in innovation are made in small, manufacturing related, baby steps. Any big technological innovation will not likely come from a manufacturer, at least not for Android products.

How an immature supply chain is helped by a mature supply chain

If you want to make a custom Android product your development and manufacturing partner, such as Hatch, plays a big role in leveraging mature supply chains to create custom products. Some suppliers in a mature supply chain are willing to support smaller production runs at a higher margin. By working with them Hatch leverages the experience and efficiency of the mature supply chain to reliably produce what is needed for the lower volume custom product.

Conclusion

Anytime a new commodity product or product category kicks off a supply chain must be created from scratch. The initial entrants do what they can to provide a ‘good enough’ early stage product, but as demand for a product grows and more companies enter into the supply chain the quality gets better. When making something custom leverage mature supply chains to gain a head start.

Whenever working with a new and immature supply chain, go slowly to find problems early. Reduce risk by thoroughly testing multiple rounds of a trial production and making clear requirements, sometimes even SOPs, for the suppliers to follow. All mature supply chains start as new and immature ones. They’re both important at different stages of a product’s lifecycle and through constant intersection help each other to grow.