Like with driving on new roads for the first time, it’s important to watch out for unexpected turns and dangerous bumps when developing custom Android hardware. Since it’s impossible to predict exactly when these turns and bumps will appear, drivers utilize safety measures like illuminating car lights, driving slowly, and carrying a spare tire. Developing custom Android hardware is no different in principle. All new projects have unforeseen bumps, but with proper safety measures in place they won’t cause major harm.

Use newer components, but not the newest

Most custom Android products are used in commercial, medical, or industrial environments. Once a brand develops a product, they want to keep it the same for as long as possible. Development is a timely and costly process compared to manufacturing an existing product.

Using newer components usually gives a product a longer production window because (on average) newer components will stay in production longer than older ones. The benefit of using older components is that they are mature, having been used in many other products. Therefore they’re more dependable as possible issues have already come to light and been addressed.

For this reason it’s good to use the latest components that the engineers are already familiar with and try to avoid ones that they’re using for the first time.

Design for Flexibility

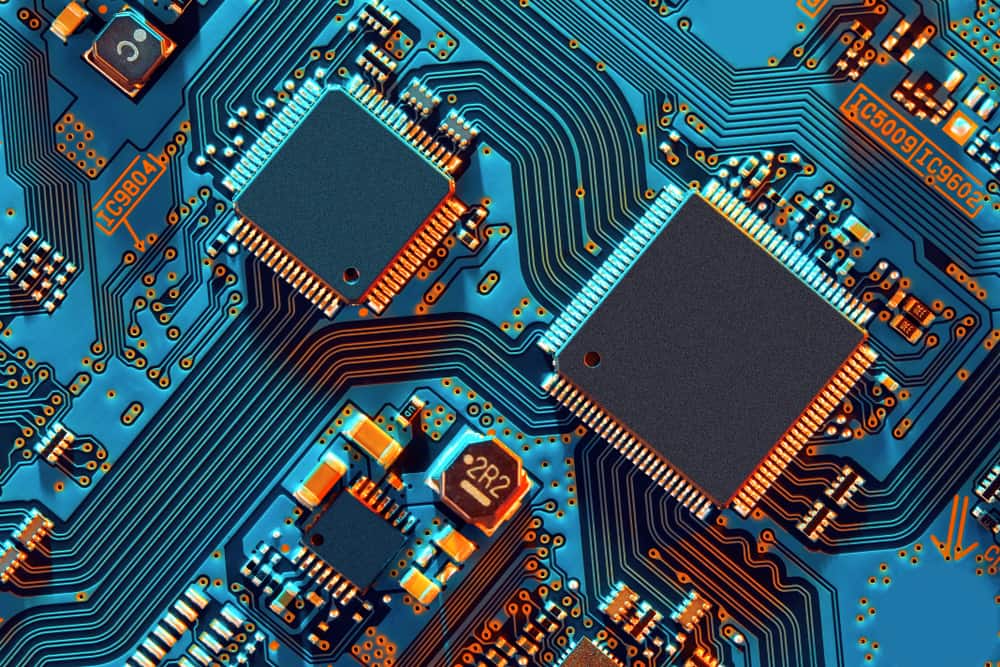

Custom Android PCBAs start with a verified reference design. Sticking with the common reference design reduces the chance for engineering problems to sneak in. When products call for supplemental electronics, the supplemental electronics sometimes need to go right on the Android PCB. A small design oversight can lead to destabilizing an otherwise reliable PCB design.

Examples include adding larger speakers, additional memory card slots, a proprietary digital media interface, or a long list of other possibilities. In most cases adding these supplemental electronics onto the board is perfectly fine and any issues are temporary ones. So, more for the sake of flexibility than stability, brands may also consider creating their own supplemental electronics independently and connecting that to a finished Android PCBA. Many brands have means to design their own supplemental electronics, but need help with the Android part.

This way if changes are ever necessary in the custom Android PCBA there’s no special consideration required for the supplemental electronics, making the product easier to update over time.

Spec for stability

While it may seem tempting to use the specs from a popular consumer device, do not. The highest spec components are custom made and reserved for large brands which produce high quantities. When those same components are available on the open market, they are rejected stock or overstock. Once that stock dries up, quality alternatives could be hard to come by. This kind of supply is both risky in quality and unstable in supply.

Hatch will take into consideration a client’s spec requests and sometime make spec suggestions based on a combination of client requests, use case, and stable mass production.

A custom Android product derives value from the unique service it provides, not from using the latest and greatest components. That’s a game for high volume consumer brands.

Take trial production seriously

Trial production is the handoff between development and mass production. The purpose of trial production is to get a limited number of products into end user’s hands so they can find problems before the product goes into full mass production.

As the last stage of the development process, trial production is the time to address and resolve problems that surface in the hands of end users. It bridges the realm of unpredictable development and the necessity of reliable mass production.

Trial production must be handled seriously. It’s not a useless formality, but a company’s last lifeline before going into mass production. During trial production the goal is to find problems. Just like with a bridge, identifying problems before thousands of people start driving over it will avoid disaster.